Mechanical engineering majors break out of the box

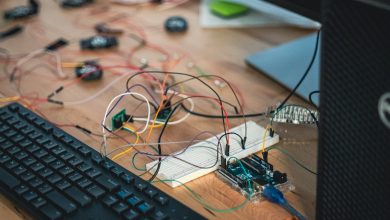

If you want to determine the wiring of a connector interface on a networking device or computer, you troubleshoot with a breakout box. This go-to tool is used mostly by electrical and systems engineers, but mechanical engineering majors are breaking out of their comfort zone and tackling a unique design challenge for the NASA Jet Propulsion Laboratory (JPL).

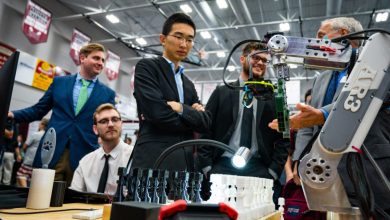

Most breakout boxes manually measure the signals between connector pins. A team of Florida Tech mechanical engineering majors have designed an automated solution that makes the process faster and less error prone. With their best in show winning design at the Northrop Grumman Engineering and Science Design Showcase, they have integrated electrical measurement and value verification electronics, cables and software with a traditional breakout box.

“The engineers at NASA JPL are highly respected and renowned worldwide,” said team leader Gerid Paquette. “It was an honor to have the opportunity to work on a project that would facilitate and contribute to the development of the next Mars Rover.”

Jumping Hurdles

The team encountered many challenges throughout the design and build process, the most prominent of which was familiarizing themselves with the required software. “The main challenges of the project were learning the ropes of PBC design software, MagicDraw, and LabVIEW, and understanding each of them well enough to complete the design of our system,” Gerid said.

As the Northrop Grumman Engineering and Science Design Showcase deadline approached, the group had to divide and conquer various tasks in order to complete their design in time. “We had two people designated as ‘experts’ for each software program,” Gerid explained. “Their task was to learn the software well enough to teach the team how to use it. This method worked very well, and we were able to successfully utilize the software.” Their strategy proved successful, the team took home the award for best in show for mechanical engineering.

Working on the project showed them that there is a real need for autonomous validation testing in industry. Breakout boxes are commonly used; however, their use is still very tedious.

“While presenting our design at the showcase, many attendees were interested in purchasing our units for their own companies because they saw the advantage of having such a device,” Gerid said.

Re-engineering

“If we were to redo the project,” Gerid continued, “we would order parts earlier in the design process. Had we completed the build earlier, we would have had more time to dive into more complex coding and smoothen the system’s simplicity and versatility.”

Working on a project that NASA JPL would assign to their own engineers, the team is confident that they have gained valuable real-world experience that will assist them in their careers. “We were able to utilize model-based system engineering principles to manage our project, which is a common practice in today’s engineering industry,” Gerid said. “We were also exposed to various manufacturing techniques that are necessary to complete a system design, such as PCB manufacturing, CNC milling and 3D printing.”

For the Love of Mechanical Engineering

The team’s advice to future student designers is to be confident, as it is the most important aspect of presenting. They attest to the fact that the presenter needs to know exactly what the assigned problem is and why it needs to be addressed.

“When you have a stakeholder involved in a project, it is also important to understand their perspective of the problem at hand, and how they want it solved,” Gerid said. “If you understand the restrictions, requirements and requests, it will be easier to convince the audience that the way in which you addressed the problem was the best way possible.”

Additionally, Gerid believes that it is helpful to use visual aids like a system diagram when describing system functionality. The group used a 2D dimensional diagram to show a use-case sequence, because they believed it would be easy to get lost or distracted with a 3D one.

Mechanical engineering majors branching out

The main takeaway from this experience for the team was discovering that one’s major does not prevent learning concepts outside of it. It showed them that breaking outside the box is necessary.

“We are a group of mechanical engineer majors that were tasked with a project that required minimal mechanical engineering input,” Gerid said. “This project combined electrical engineering, systems engineering and computer science. Using our general engineering knowledge, mindset and learned research techniques, we were able to hone the skills necessary for designing a successful system.”