Robotics and Spatial Systems Lab: Motoman, the Real 3D Printing

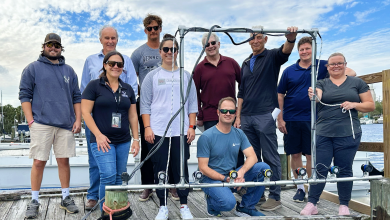

Since my job last year at the robotics and spatial systems laboratory was so awesome, I decided to continue working there this school year. Apart from helping and creating different workshops and tools for Dr. Larochelle’s intro to mechanical engineering class, I’m starting a brand new research project that I’m incredibly excited about. I, along with another team of about five students, will be working with a robotic arm called Motoman in order to do “real” 3D printing.

The Motoman SV3 is a general-purpose robotic arm with a reach of a little over two feet and six degrees of freedom. Robotic arms like these are commonly used for manufacturing engineering in order to do repetitive motions that need delicate or intricate movements. These types of robotic arms are also commonly used in the food processing and packaging industry because they come equipped with pneumatics. The devices are preferred while working with food since air has no byproduct, won’t contaminate anything and it’s inexpensive.

Here at the robotics lab we like to do fun, whimsical and really cool projects. Motoman has been used in other projects such as Motodad, where “he” wanted to procreate so he built himself a little offspring, RuBot, that can take a Rubik’s cube in any configuration and solve it, and he can even play checkers or fold origami in projects such as Motocheck and Robogami.

The goal of our current project is to equip a print head to Motoman and create motion algorithms to be able to do 3D printing with the arm. The reason to expand upon robotic arm 3D printing as opposed to just using the typical 3D printers is to reduce the motion limitations of the typical x-y printing with planar elevations. The x-y printing can reduce arc strength while printing spherical objects because the material is laid out laterally. If the robotic arm was placed on a programmable moving platform, the limitations of a “printing table” would be pretty much infinite. This could open up the possibility of 3D printing buildings! In the future, this could be a very practical where resources are limited and additive manufacturing has no resource waste. Not to mention, it’s also really cool to just print stuff out with a big robotic arm! I’ll be sure to keep you updated as this project progresses.

The goal of our current project is to equip a print head to Motoman and create motion algorithms to be able to do 3D printing with the arm. The reason to expand upon robotic arm 3D printing as opposed to just using the typical 3D printers is to reduce the motion limitations of the typical x-y printing with planar elevations. The x-y printing can reduce arc strength while printing spherical objects because the material is laid out laterally. If the robotic arm was placed on a programmable moving platform, the limitations of a “printing table” would be pretty much infinite. This could open up the possibility of 3D printing buildings! In the future, this could be a very practical where resources are limited and additive manufacturing has no resource waste. Not to mention, it’s also really cool to just print stuff out with a big robotic arm! I’ll be sure to keep you updated as this project progresses.